Laboratory for Ultra-Precision Surfaces, L-UPS

In 2019 the Laboratory for Ultra Precision Surfaces (L-UPS) was established in a brand-new building at one of the UK’s six National Labs – SciTech Daresbury, near Warrington. Daresbury is operated by STFC (Science and Technology Facilities Council), which is responsible for major National scientific research facilities in the physical sciences, located both in the UK and abroad. The logic for basing L-UPS at Daresbury was to foster strategic research links with STFC, provide access to local facilities, and benefit from working in a thriving research community. This has borne fruit - Daresbury hosts the Hartree Centre supercomputer facility, and a funded collaborative project on modelling physics and chemistry of material removal is starting in mid 2021.

The group has several UK industry partners, and is fortunate in having overseas collaborators contributing to projects, notably in the USA, Spain (Tenerife) and China.

Meet the team

Prof. David Walker

University of Huddersfield

Dr Guoyu Yu

University of Huddersfield

Dr Hongyu Li

The University of Huddersfield

Research

L-UPS research concerns advanced processes for the manufacture and measurement of complex ultra-precision functional surfaces. Our work aims to achieve tolerances well below the typical levels of a micron or so, that would be common in the work of Huddersfield’s Centre for Precision Technologies. In practice, that means tens of nanometres or below in overall form, and a few atoms in surface texture (‘roughness’). Our research spans a range of activities, from the fundamental physics and chemistry of removal mechanisms at one extreme, through technologies for process-automation, to meeting real demands from the world around us.

The team is researching innovative process strategies in both hardware and software, implemented on robot and computer numerically controlled machines, plus developing metrology methods to close the process loop. Working with industry partners, our primary aims are to improve our understanding of the fundamental physics and chemistry behind processes, improve process-predictability and quality, and automate process-execution. The work of the lab brings together a host of disciplines, including materials science, software development, computer modelling and high-performance computing, robotics and AI, surface-metrology, mechanical engineering and modern sensor technologies.

Projects

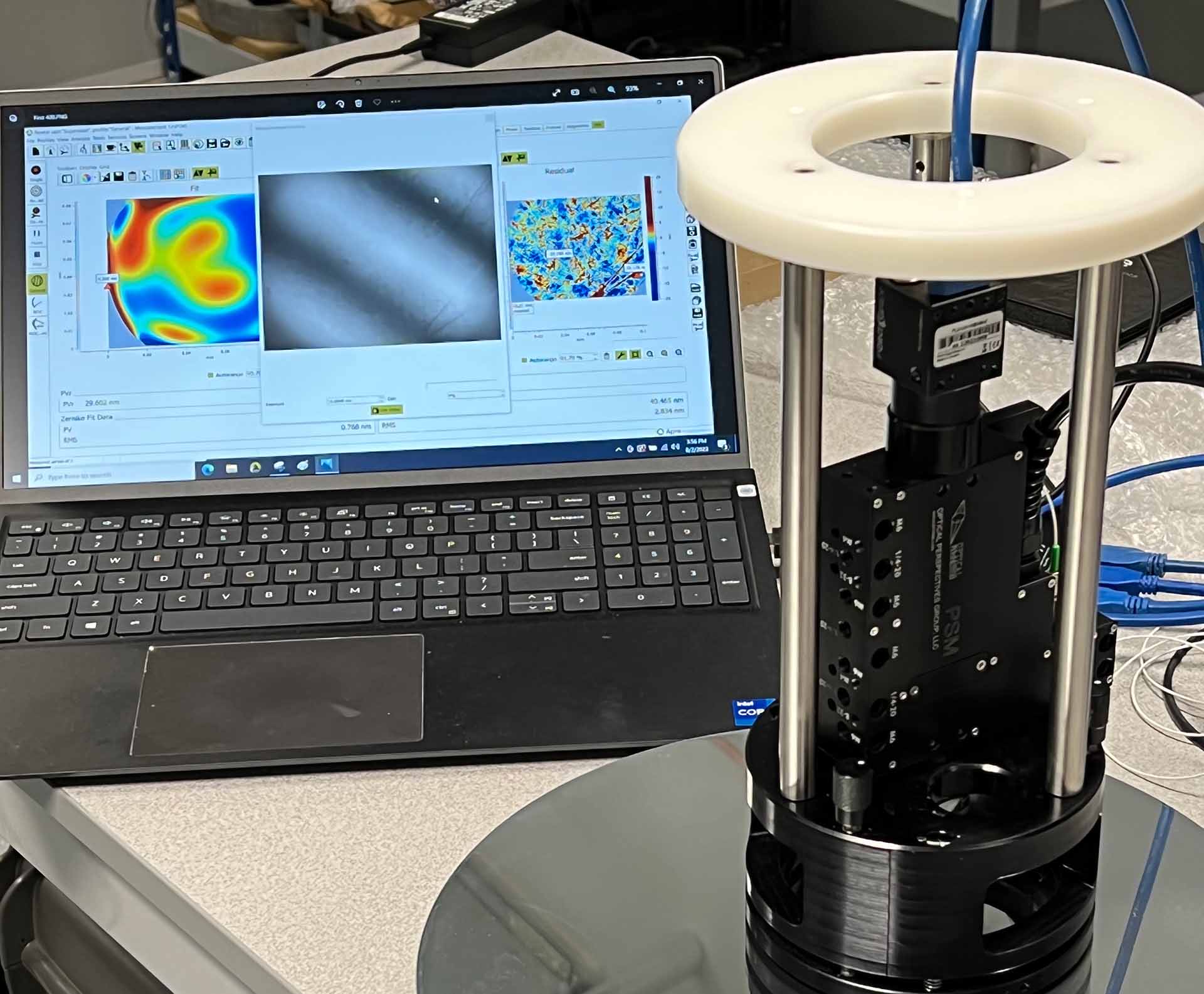

- Automated, high dynamic-range, free-form surface-metrology, funded by EPSRC Future Metrology Hub, PI Prof David Walker

- Transferring Technology in Optimised Metal Mirror Fabrication STFC funded project led by Huddersfield with industry partners, PI Dr Guoyu Yu

- Under the Skin of Polishing – Nano to Macro, EPSRC funded project, led by Huddersfield with Liverpool John Moores University, Sheffield Hallam University, STFC Hartree, and industry partners, PI Prof David Walker

- Development of a force measuring table, collaboration with the Fine Optical Engineering Research Center, Chengdu, China

- Training and research partnership with the Instituto de Astrofisico de Canarias (IAC, Tenerife)

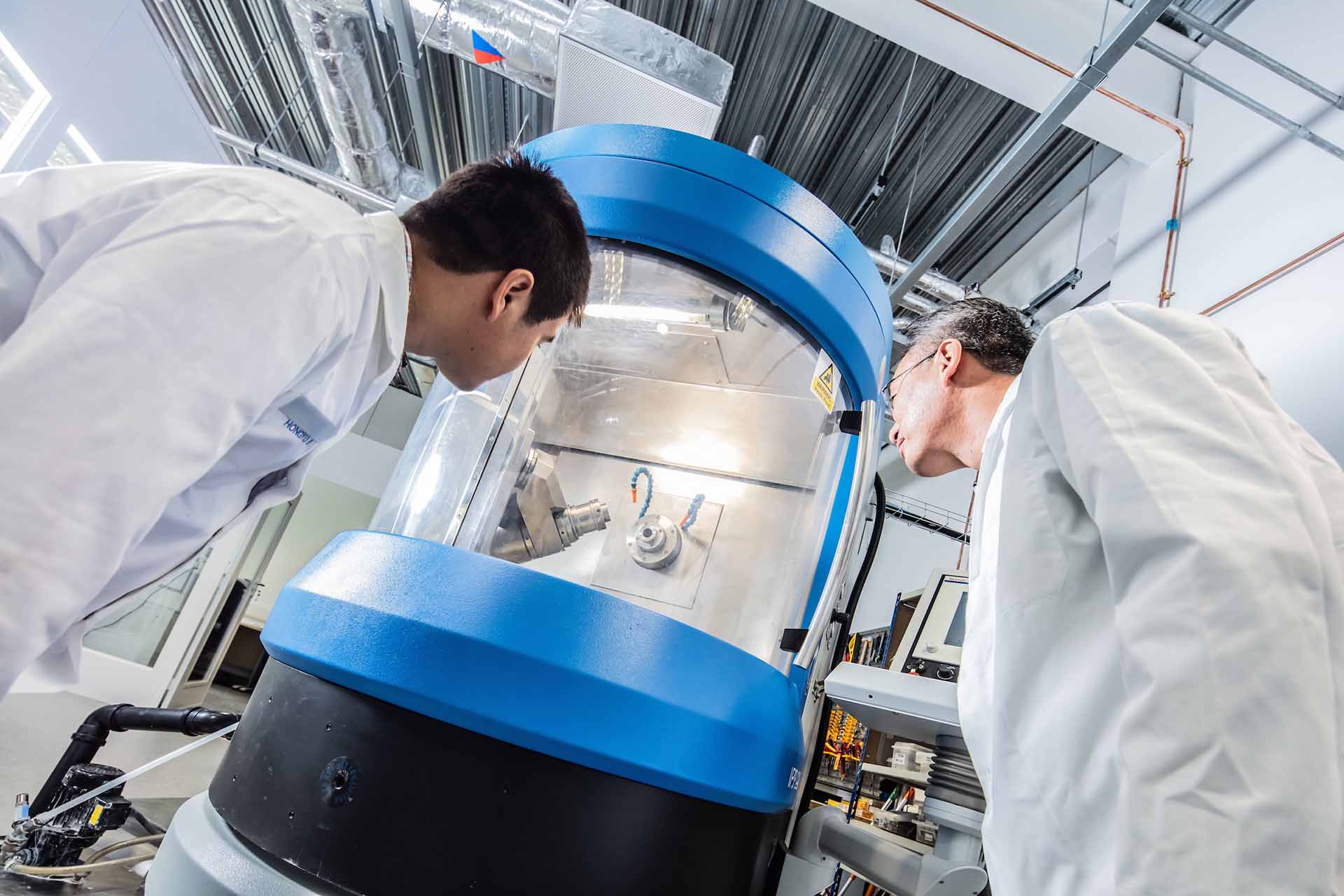

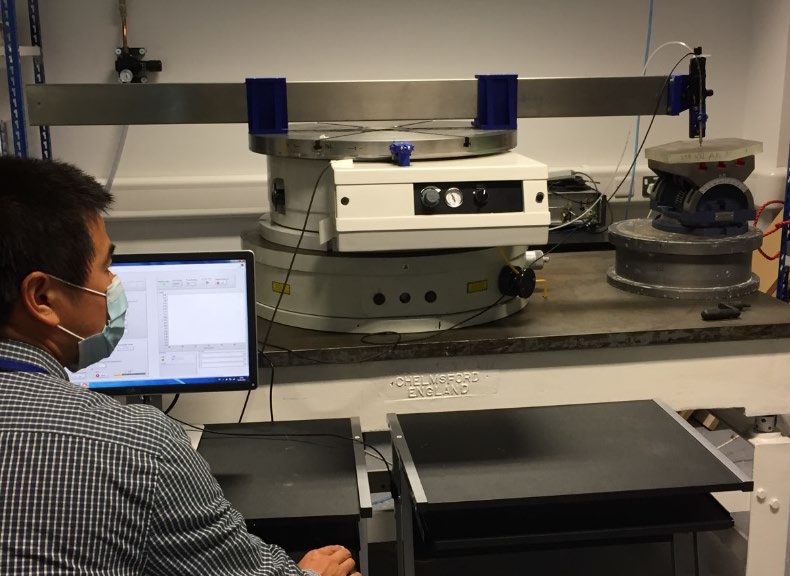

Facilities and Equipment at Daresbury

The Laboratory for Ultra Precision Surfaces has an impressive range of state-of-the-art, highly specialised equipment, along with a highly skilled and experienced team of researchers.

Our facilities are available for use by academics and industry.

Facilities Image Carousel

Other Equipment

- Fanuc 6-axis 2000iB robot (110KG payload, 3m reach) with polishing spindle

- Kemet 24-inch, 3 ring, precision flat lapping machine

- 6-axis static/dynamic force measuring table

- Fisba interferometer

- SIOS displacement interferometer

- Hexagon measuring arm